Synthetic or Mineral Based Oils?

Many of our customers often ask us whether they should use synthetic-based lubricants or mineral oil-based lubricants.

There is no standard answer to this question as there are so many variables for example, what type of machine or equipment are you using? what is its application? how often will it be used? is it for indoor or outdoor use? and many other application-specific factors.

Advantages of Mineral Oil-Based Lubricants

The key plusses for using mineral oil-based lubricants are that they provide higher quality of solubility when used with additives and as such are more versatile for more popular applications. Their compatibility with a wide range of seals is excellent and are less expensive than their synthetic-based lubricant counterparts.

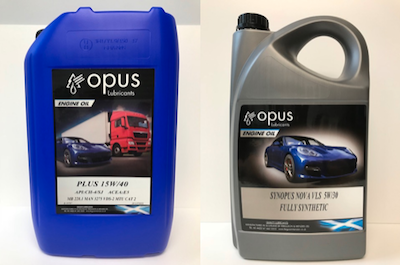

Ferguson & Menzies manufacture and supply Fully Synthetic, Semi Synthetic and Mineral Based Lubricants. Ask us which is best for you.

Advantages of Synthetic-Based Lubricants

Synthetic-based lubricants are much more tolerant and resilient when operating in extreme environments and temperatures, are less prone to oxidation and have a longer operating and storage life than mineral oil-based lubricants.

Theoretical Scenario

You have a regular application which operates in a low temperature environment and need a lubricant that can perform to a consistent standard over a given period. You may get longer life from a synthetic-based lubricant as well as knock on benefits such as reduced downtime and longer operating time due to fewer oil changes.

However, in conjunction with the environment’s low temperature there may also be a high level of airborne contamination which may result in the need for more regular oil changes. In this instance it may be more cost effective to opt for a mineral oil-based lubricant.

Conclusion

Never choose a lubricant based on only a few factors such as machinery type or reputation. Your individual circumstances should be the only consideration. A good starting point is to prepare a list that covers all the parameters of your application. This should include environmental characteristics, machinery type (make and model), timescales, etc.

You might like to try Ferguson & Menzies Oil Selection Tool to help you make an informed choice as to the right lubricant for your application. Alternatively please contact us for advice on +44 (0)141 445 3555, email us on or send us an enquiry.